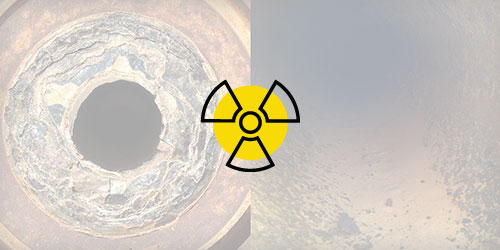

Removing embedded NORM from metal and scale with traditional mechanical cleaning methods produces unreliable results, requires removing equipment from operations and creates a lot of NORM water waste. UHP cleaning is only effective on some scale areas that can be reached – it will not remove it from the steel pores.

To chemically remove NORM contamination embedded in the metal, we start with circulating FQE Scale-Solv SS to remove the scaling and build-up on the equipment walls.

Where there is no scale, we would instead utilize our patented chemistry FQE NORM-Clear to draw the embedded NORM heavy metals from the parent metal. Using this method will not cause corrosion, erosion, or damage to common internal equipment components.

Benefits of our NORM products