Contaminants

Barium Sulfate Scale

Barium sulfate scale is common to refinery and utility operations and is a hard scale that restricts flow in the system when it builds up, costing the industry hundreds of millions in lost production.

Why is Barium Sulfate Scale a problem?

Removing Barium Sulfate Scale

Current Industry Practices

What is Barium Sulfate Scale?

Deposition of scale forming salts on equipment surfaces in many industrial systems such as oil and gas production, desalination, pulp and paper, cooling and boiler operations is a well-studied problem.

The scales are precipitated as a consequence of a disturbance in system pressures, temperatures and the mixing of incompatible waters. The common sulfate scales (barite, celestite, gypsum) are sulfate salts of the alkaline earth metals.

Since they have many similar physical and chemical properties, they often precipitate together.

Why is Barium Sulfate Scale a problem?

Although not as common as calcium carbonate and calcium sulfate scales, barium sulfate deposits have long plagued oil field and gas production operations. These scales interfere with fluid flow, enhance corrosion, causes production losses, result in equipment replacement, damage equipment and may host bacteria. Scales can develop in the formation pores near the wellbore – reducing formation porosity and permeability. It can block flow by clogging perforations or forming a thick lining in production tubing. Barium sulfate scale problems costs the oil and gas industry hundreds of millions of dollars per year in lost production.

White Paper

NORM Decontamination

We recently completed the world’s first specialized NORM chemical application on a Depropanizer in Texas, achieving exceptional results.

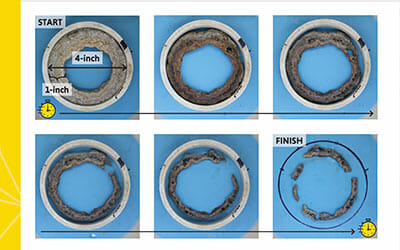

Barium Sulfate Scale Removal with FQE® Barium-Clear

FQE Chemicals has developed a proprietary chemical product designed specifically for hard scale removal. A novel technique using dissolvers with catalytic activators enhance the rate of dissolution and has proven effective with a wide variety of scales and most specifically with barium sulfate scale.

FQE Barium-Clear is formulated to prevent re-deposition of the scale which is a common failure of many chemical treatments. Additionally, as a non-acidic product, the byproducts of reaction do not act as excellent initiators for the reformation of scale deposits common to spent acid solutions.

Applications

Dissolution of Barium Sulfate Scale in Oil Production

Application

FQE Barium-Clear is typically applied as an aqueous solution with fresh water with a soak period of 6 to 24-hours for downhole applications. On surface equipment, applications are typically done through circulation of the treating liquid at temperatures of 170-180°F (77-82°C). Circulation times will vary depending on the severity of scaling, but 4 to 16-hours is common.

The Benefits

A simple, effective and efficient liquid chemical method to resolve an old problem. Capable of reaching areas that mechanical methods cannot.

1

Non-acidic composition, completely personnel and equipment safe

2

Effective, efficient scale dissolution for a variety of hard scales including barium sulfate

3

Anti-redeposition formula to maintain a homogenous fluid and prevent rescaling

4

Cost effective

5

Low toxicity product

6

Non-corrosive on most steel, thus safe

Current Industry Practices

Once formed on the equipment surfaces, barium sulfate scale is extremely difficult to remove. Accumulated solid layers of impermeable scale can line tubing and are less easily removed. Sometimes, tar-like or waxy coatings of hydrocarbons protect the scale from chemical treatment.

Chemical scale removal is often the first, and lowest cost approach, especially when the scale is not easily accessible. With chemically reactive scales such as calcium carbonate, acid treatment to cut through the scale blockage is a traditional practice. Strong chelating agents break-up acid-resistant scale by isolating the scale metallic ions.

However, chelants are slow to react and often offer minimal liquid saturation points. Consequently, the surface area to volume ratio is low and the speed and efficiency of the removal process is too slow to make this chemical treatment a practical removal method.

For hard scales, such as barium sulfate, mechanical removal (scraping, sand blasting, chipping, jetting, controlled explosives) is the technique most often employed. Because scale is rarely deposited evenly on tubular goods, milling technology power requirements vary greatly. When motors cannot supply the power needed for the bit to cut the scale, the motor stalls and the milling process stops.

Even with effective milling practices, residual scale surface in the tubing or other equipment encourages new scale growth and makes inhibition treatments to block nucleation much more difficult. A clean, bare steel surface is more effective in preventing new scale growth.

When these processes are ineffective, production operators are often forced to shut down production, move in workover rigs, to pull damaged tubing out of the well, and replace the tubing.

Nevertheless, barium sulfate is extremely resistance to both chemical and mechanical removal.