Contaminants

Hydrogen Sulfide Control

Hydrogen Sulfide is an extremely hazardous gas found in the industry and can have extremely detrimental health effects in addition to being both flammable and corrosive.

Why is Hydrogen Sulfide a problem?

Removing Hydrogen Sulfide

Current Industry Practices

What is Hydrogen Sulfide?

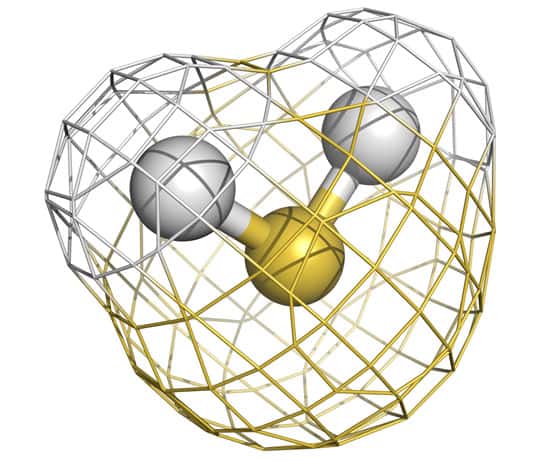

Hydrogen Sulfide (H2S) is commonly associated with the smell of rotten eggs. It’s a colorless, heavier-than-air, poisonous and corrosive gas.

Hydrogen sulfide can be created by bacterial decomposition of organic matter such as septic tank debris and faecal material. This process is conducted by sulfate-reducing bacteria (SRBs) in the absence of oxygen. In the presence of water, it is acidic and is known as hydrosulfuric acid. Additionally, H2S can be generated in crude oil and gas feeds through the reaction of sulfur and hydrogen. The refiner facilitates this reaction specifically to make H2S which is easier to remove from the products than elemental sulfur. This is the cause of the corrosion in sour gas or sour oil processing equipment. However, it can be neutralized using hydrogen sulfide control methods.

Why is Hydrogen Sulfide a problem?

Hydrogen sulfide is lethal by inhalation at concentrations of 500ppm; it can quickly kill animals and humans at this concentration. The odor associated with hydrogen sulfide can be detected at concentrations as low as < 1 ppb. Hydrogen sulfide is an olfactory desensitizer, meaning that short exposure to even low concentrations of the gas stops your ability to smell the chemical.

H2S Control with FQE® H2S Scavenger

FQE H2S Scavenger is a water-based, proprietary polymeric product used for hydrogen sulfide control. There are three critical issues associated with any H2S scavenger:

1

Rapid rate of reaction

2

Non-reversible reaction path (no reversion to H2S)

3

Cost efficiency per mole of H2S

FQE H2S Scavenger meets all above conditions. It efficiently works in both liquid and steam phases.

The reaction of FQE H2S Scavenger with Hydrogen Sulfide is nearly immediate and is non-reversible. It is advised that the client have good chemical dispersion equipment to optimize the use of the product. As with all competitive products, this is a contact-dependent reaction.

Applications

This H2S Scavenger product is used in refinery operations, oil and gas production, wastewater treatment operations and any industry where H2S is a concern.

Current Industry Practices

One inexpensive process for Hydrogen Sulfide removal from gas streams is to pass the gas through a bed of hydrated iron oxide. The iron (or a similar cation) will replace the hydrogen atoms in the H2S molecule to form a metallic sulfide and water. This is a common practice for packed, fixed-bed reactors where iron oxides are the standard metal used. While this is a cheap process, the packed beds must be replaced when the iron ceases to be active. The iron sulfide formed can be regenerated by flooding the iron sulfides with water and aerating the metal. This process produces elemental sulphur.

Note that the iron sulfide created in the packed beds can be pyrophoric and may create H2S if the metal is exposed to acidic pH conditions.

Since H2S is acidic, one practice to remove the hazard and corrosive nature of Hydrogen Sulfide is through alkaline neutralization of the acidic protons present within H2S. This process is an effective, rapid method to negate the concerns of H2S and involves the formation of a salt. The reaction of forming a salt with many alkaline products such as caustic soda results in the possibility of the reversion of the salt to hydrogen sulfide gas under acidic pH conditions or in elevated temperatures. It is this reversion of the salt back to release hydrogen sulfide that makes neutralization an unacceptable process.

When it comes to amine reaction products, the industry currently uses many different types of amines. Most of the amine-type chemistries are either triazine-based or an alkanolamine product.

Alkanolamines like monoethanolamine (MEA) and diethanolamine (DEA) are the products used in the refinery Sulfur Recovery Units (SRU). Under the conditions of refinery application, H2S is converted to elemental sulphur. These products are also used in oil field gas production operations to mitigate H2S. They are functional, but less cost effective, as they only react on a single molar basis.

Triazine–based products are varied in their structures depending on the starting materials. They are functionally superior, because 2 moles of hydrogen sulfide can be controlled per mole of the chemical. However, in reaction with H2S, the triazine product typically forms an insoluble solid precipitate called dithiazine. This solid is the cause of much concern in the oil field, as the dithiazine particles plug valves, coat pipelines, contactors, and treater towers, stopping the flow. If this problem begins in pipelines and the deposits cannot be pigged out, it will eventually lead to pipeline replacement—at a very high cost.

Triazines are cheaply made and therefore are bordering on commodity products. As they are inexpensive, you will find them in everywhere in the oil field for H2S control.