Case History

Innovative chemical scale treatments boost well production at a fraction of the cost and effort of traditional acid treatments

Chemicals Utilized

Effective at dissolving carbonate scale and as a substitute for hydrogen chloride. Scale-Solv SS is non corrosive to metals, allowing for treatments to be performed with downhole equipment still in the hole reducing rig time and rig expenses.

Turnkey barium scale solutions partner:

Ba Chemicals

13120 N. MacArthur Blvd

Oklahoma City, OK 73142

405.205.6512

These successful case studies were executed by our distribution and service partner Ba Chemicals.

1

An operator in Colorado saves 75% per well with FQE Scale-Solv SS treatment.

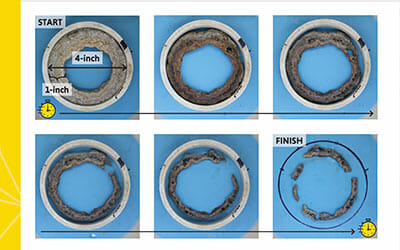

Five shallow gas wells were treated with 12 bbls of FQE Scale-Solv SS. The chemical was set for 1-hour, then ran the pumping units for 30-minutes, followed by a shut-in for 2-hours. The wells were now returned to production. The treatments required no workover rig, and the only equipment used was a bobtail vacuum truck. Operator saved approximately 75% per well versus traditional acid job and increased production over 10x.

2

Oklahoma operator reduces costs by 40% utilizing FQE Scale-Solv SS for remedial acid treatment.

The operator experienced a decline in production, and there were indications of build-up around the perforations requiring treatment to restore production. An 8,000-gallon treatment was designed and pumped down the tubing with a packer to isolate the perforations.

The treatment pressures and rates indicated a reduction in the scaling. Since FQE Scale-Solv SS is safe for production equipment, the well was immediately returned to the rod pump, eliminating multiple days of rig time and reducing costs by 40%. Production rates have increased, and the oil cut has improved.