OIL PRODUCTION APPLICATION

Dissolution of Barium Sulfate Scale in Oil Production

Barium sulfate deposits have long plagued oil field and gas production operations. These scales interfere with fluid flow, enhance corrosion, cause production losses, result in equipment replacement, damage equipment and may host bacteria.

Scales can develop in the formation pores near the wellbore – reducing formation porosity and permeability. It can block flow by clogging perforations or forming a thick lining in production tubing. Barium sulfate scale problems costs the oil and gas industry hundreds of millions of dollars per year in lost production.

FQE Barium-Clear is effective not only at removing and breaking down the scale, but also completely dissolving it into a liquid phase.

Applications

Producing Wells

Batch treatments to clear tubing, casing and perforations

Injection Wells

Batch treatments to clear tubing and perforations effectively lowering injection pressures with minimal downtime

Surface Equipment and Pipelines

Batch treatment of flowlines, pipelines and surface equipment to clear scale

Preventative Maintenance Treatments

Continuous treatment of FQE Barium-Clear to the problem area to prevent the reforming of scale

Case Histories

1

An injection well flowline for the Northwest Chandler Waterflood Unit in Lincoln County, Oklahoma was plugged with Barium Sulfate scale reducing flow to 150 bbls/day from 1100 bbls/day. 1500 feet of flowline was treated with 60 bbls of FQE Barium-Clear for 5 hours. The injection rate after treatment returned to 1100 bbls/day with drastic reduction in pressure.

2

An injection well in the Northwest Chandler Waterflood Unit was injecting 150 bbls/day at 1400 psi. The well was treated with 60 bbls of FQE Barium-Clear and shut in overnight. Operation resumed the next day following the treatment at an injection rate of 1100 bbls/day at 800 psi.

3

An active pumping oil well in Ellis County, Oklahoma was having continual iron sulfate scale problems requiring 6 workovers per year. A 30 bbl FQE Barium-Clear treatment was performed for the initial clean out of the wellbore followed by a trace continuous injection of FQE Barium-Clear as a treatment program. The well has been operating for 8 months with no scale build-up or workovers needed.

4

A surface injection pump in Noble County, Oklahoma was quickly building Barium Sulfate scale causing pump failure every 2-4 weeks. A locked-up and scaled-up pump was circulated with 12 gallons of FQE Barium-Clear. The treatment removed the scale and freed the pump after 4 hours. The well was placed on a continuous treatment program which has prevented further scale build-up.

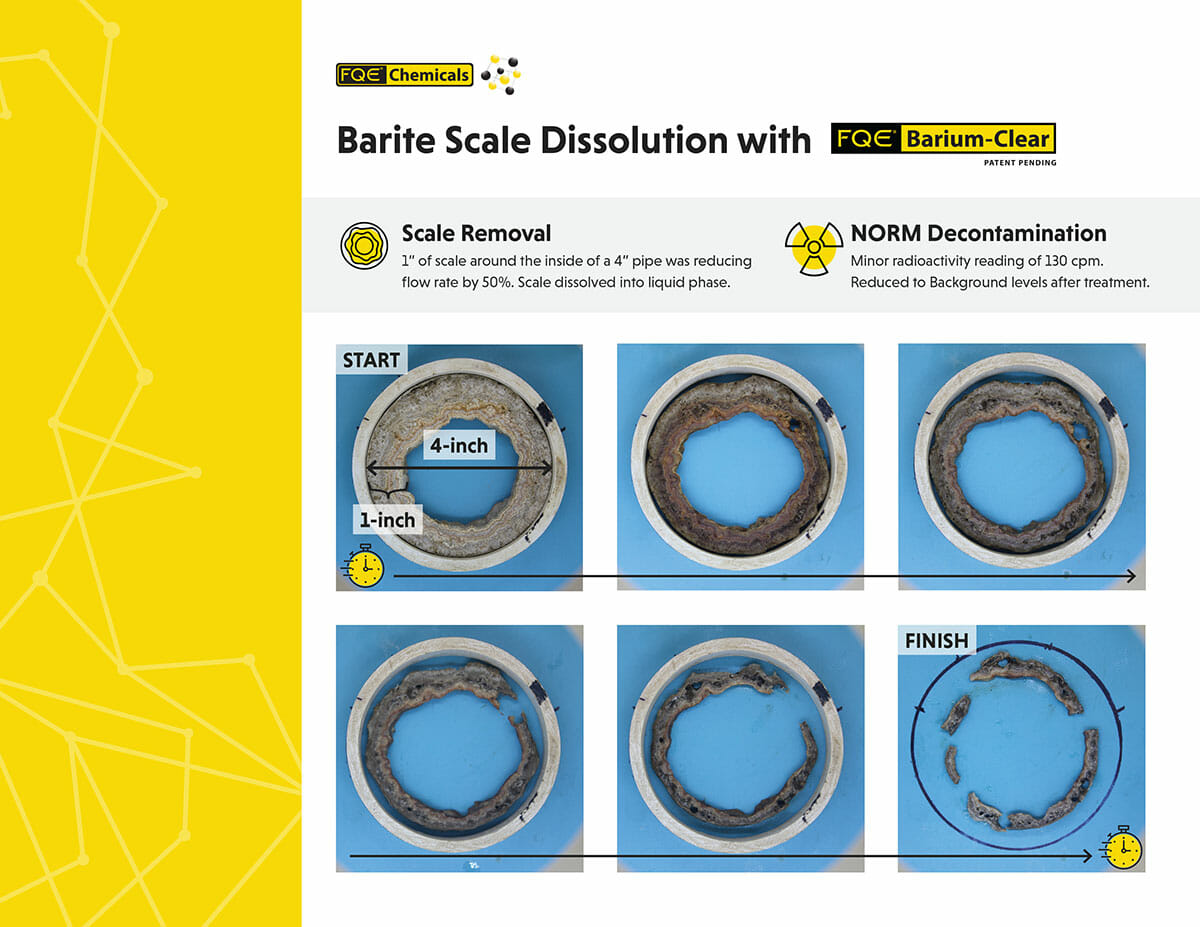

SCALE and NORM REMOVAL FROM A PIPE

Barium Scale Dissolution

This 4” pipe had a 50% flow rate due to a build-up of hard barite scale and had a minor radioactive reading of 130 CPM.

After a trial application of FQE Barium-Clear, the scale was dissolved from all sides into liquid phase, which could then be flushed from the system. The flow rate through the pipe returned to full capacity, and the radioactivity was successfully measured at background levels.