Applications

Railcar Cleaning Chemicals

Our innovative railcar cleaning system is designed to target the specific fouling in your railcars and apply chemicals for that foulant using a vapor phase injection application.

Efficient Railcar Cleaning Chemicals

Due to growing oil production and pipeline bottlenecks, the demand for railcars to transport oil and gasoline has been surging. This increase in demand has led to a thriving railcar cleaning market where railcars are traditionally cleaned using a combination of expensive mechanical equipment as well manual labor.

These methods present numerous concerns; including confined space entry in a hazardous atmosphere and lost time due to extended cleaning durations. Safe and effective cleaning of railcars is crucial to maintaining regulatory compliance and financial performance.

FQE Chemicals provides an innovative railcar cleaning system that is designed to significantly reduce cleaning durations and waste effluent volumes via a vapor phase injection application. Furthermore, our process does not require manned entry and therefore eliminates manpower exposure to heat, high-pressure media, hazardous vapors, and potentially explosive atmospheres.

Railcars our Chemicals Clean

Crude cars

Food grade

Asphalt

High pressure tank cars

Change of service to ethanol

Use of FQE Chemicals product line and application process for railcar cleaning will increase cleaning efficiency and thereby allow you to reduce cleaning times and maximize the profitability in a safe and competent manner.

Advantages

1

Reduced manpower exposure

By significantly reducing manpower exposure, you eliminate exposure to dangerous conditions such as heat, high-pressure media, hazardous vapors, and potentially explosive atmospheres.

2

Clean more railcars in less time

One can deduce: if your railcars are cleaned faster, not only will it reduce man-hours, but they’ll get back to making business happen. Thus, boosting your financial and business performance.

3

Significantly reduce waste volumes

Simply put, you’ll save money on waste disposal costs.

4

Recover organic content

With rapid phase separation, recover hydrocarbon content as an unexpected revenue stream.

Using FQE Solvent-H – Before and After of a cleaned out crude oil railcar

Railcar Cleaning Application Process

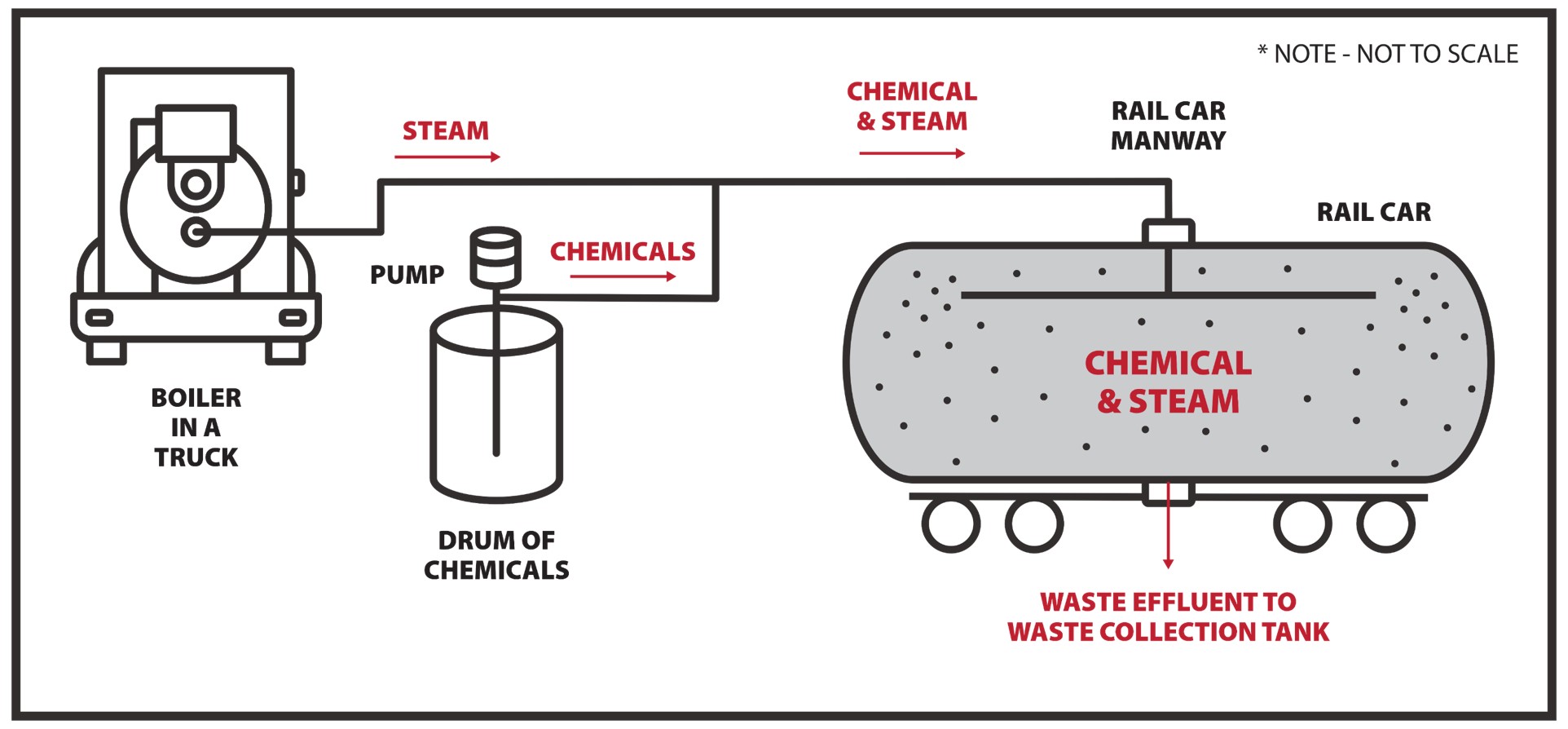

To proceed with a railcar cleaning process, the bulk fluid (crude, asphalt, ethanol, etc.) is first de-inventoried. This is then followed by the injection of the FQE Chemicals product directly into steam at the manway of the railcar. The steam acts as a carrier medium and is designed for effective distribution of the product throughout the railcar.

As the product coats and penetrates the internals of the railcar, the heavy organics will be dispersed and liquefied. Sludge deposits, which would otherwise remain as solids, are liquefied and can be pumped out of the bottom drain for phase separation and waste disposal.

Change of Service Railcar Cleaning Application

Additional products may be applied in a change of service application to convert a railcar from dark oil to clear fluid service. In these applications, FQE Pore Clean may be used as a high-performance penetrant to effectively pull hard-to-reach hydrocarbons out of the porous steel surfaces.

Full decontamination of hydrocarbon content in the porous steel eliminates the potential for product cross-contamination and thereby preserves product quality for transport.