Case History

LEL-Vapor Enhances Degassing by 1500x

Weeks into Days: Degas the vessel

CHALLENGE

Process units, vessels, and tanks may contain dangerously high levels of vapors that exceed LEL or HES exposure limits.

SOLUTION

- Using water with a modest amount of LEL-Vapor can be used to treat the vapor space, capturing and removing these problematic vapors, fumes, and odors.

- Enable water with LEL-Vapor to be atomized or sprayed into the void space in question to knock down the vapor.

RESULTS

Reduces time waiting for diesel fill and drain degas process from the typical days/weeks to hours.

Takes the unpredictability of time wasted and waiting for LEL limits to be reached before entry.

Less time degassing means less flare (TO) time; and less TO costs.

Recoverable volatile hydrocarbon can be recovered and reprocessed.

Gasoline Tank Degassed in Hours

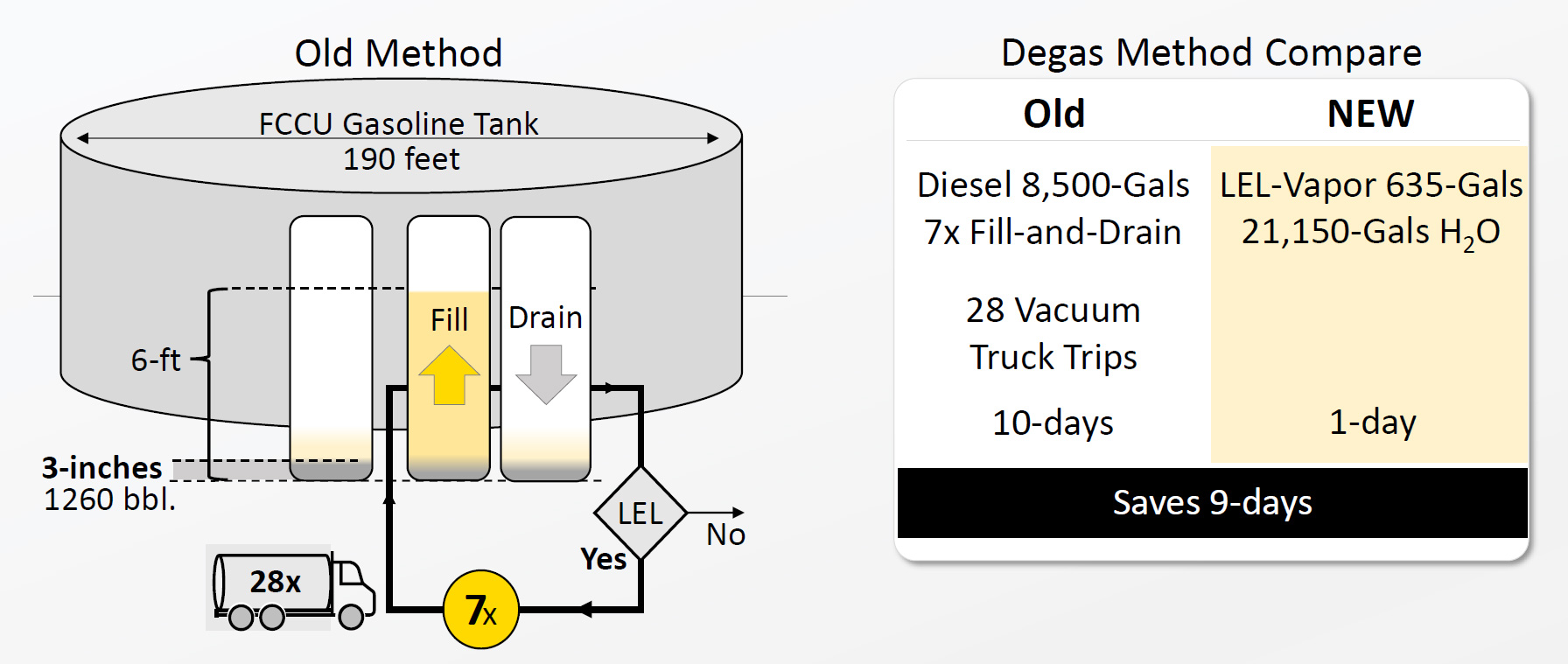

In the past, the refinery utilized the diesel fill and drain technique to degas a gasoline tank.

However, this method proved to be inefficient, involving the time- consuming process of pumping diesel into the tank and subsequently draining it via vacuum trucks. After each fill and drain cycle, the Lower Explosive Limits (LELs) remained at unsafe levels, necessitating repeated cycles. In this case, it took ten days and seven discrete fill and drain cycles, consuming nearly 60,000 gallons of diesel.

In contrast, using approximately 20,000 gallons of water and a small percentage of LEL-Vapor, the tank was successfully degassed within just one day.

CHEMICALS UTILIZED

Unit Clearing for Degassing Vessels, Units, and Tanks

The FCCU unit had to temporarily take a gasoline storage tank out of service. The 190 feet diameter tank had the roof landed on the legs (6’3″) creating a void space with volatile LEL readings. A residual tank heel of only three inches, equivalent to 1,260 barrels, remained as tank bottoms. The Lower Explosive Limits (LELs) in the vapor space exceeded permissible levels for safe entry into the tank. Typically, the tank’s owner would employ a fill-and-drain technique using diesel fuel to mitigate volatiles or emissions. While this method is straightforward, it involves a time-consuming process of loading approximately 8,500 gallons of diesel into the tank, followed by four vacuum truck trips to drain the tank each time. Moreover, the effectiveness of this process is not guaranteed. It took seven iterations and nearly 60,000 gallons of diesel to degas the residual volume in the tank with 28 vacuum truck loads. This process proves to be inefficient, resulting in significant downtime for the tank, which often lasts around five weeks.

Unlocking the Power of Water

LEL-Vapor was used to activate water, facilitating the combination of incompatible oil and water phases to degas the tank within a day. LEL-Vapor utilizes cutting-edge technology to reduce the free energy, enabling the two immiscible phases to remain blended without any separation. Notably, this is achieved without the need for surfactant soap chemistry. By introducing minute amounts of LEL-Vapor into the water, typically at a few percent concentration, the process facilitates and enables the water to capture the vapors effectively.

-

Old Method: Diesel flush (fill-and-drain), measure LEL’s

-

Texas Refinery spent 7x cycles with 4-tankers to fill once = 28 total

-

-

New Method: Used LEL-Vapor in water and degassed tank in 1-day

-

Time savings along with other savings – H2O, Emissions(VOCs/LELs)

-

Predictable, COD friendly, No waste, ↓VOCs/emissions/LELs/TO time

-

1500 Times Better

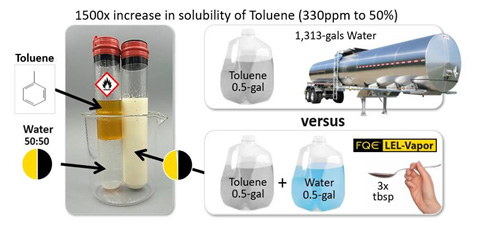

Toluene closely resembles benzene, featuring an additional carbon atom attached to the same aromatic benzene group. Due to their high volatility, benzene and toluene readily evaporate and become gas vapors. Consequently, it’s not uncommon to exceed Lower Explosive Limit (LEL) in any open void space.

To demonstrate the lack of solubility of toluene and water, one can attempt to mix them in a 50:50 solution. Even with agitation, these two liquids only partially combine and quickly separate once mixing ceases, typically within seconds. To employ water for capturing half a gallon of toluene, one would need 1,313 gallons of water, a quantity that can be measured in tank wagon size quantities. Alternatively, by introducing a small amount of LEL-Vapor to the water and gently mixing, the two liquids readily form a unified mixture, effectively capturing the toluene. At this point, the toluene is not stratified at the surface and is not evaporating. To capture the same half gallon of toluene, only a single half gallon of water and three tablespoons of LEL-Vapor would be required.

Enhanced Safety While Saving Time

The process is safer, as we’re using water and not using an ignitable component of the fire triangle (source) to capture the harmful, flammable, and carcinogenic vapors. LEL-Vapor is wastewater friendly and is designed with COD in mind.

No diesel fuel was harmed in the making of this experiment.