Increase your reserves without having to drill new wells

Barium sulfate deposits have long plagued oil field and gas production operations. These scales interfere with fluid flow, enhance corrosion, cause production losses, result in equipment replacement, damage equipment and may host bacteria.

FQE Barium-Clear is effective not only at removing and breaking down the scale, but also completely dissolving it into a liquid phase.

Why choose FQE Barium-Clear?

-

Non-acidic composition is personnel and equipment safe

-

Efficient scale dissolution for a variety of hard scales including barium sulfate

-

Anti-redeposition formula to maintain a homogeneous fluid and prevent rescaling

-

Low toxicity product

-

Non-corrosive on most steel

Contact us today to learn more

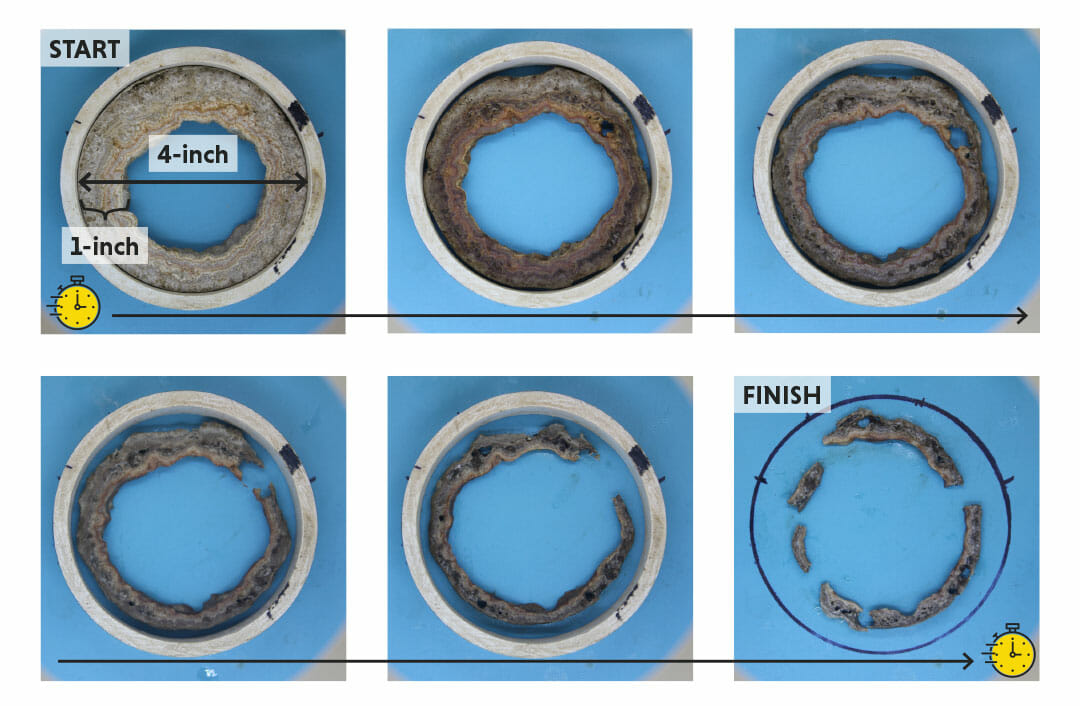

SCALE and NORM REMOVAL FROM A PIPE

Barium Scale Dissolution

This 4” pipe had a 50% flow rate due to a build-up of hard barite scale and had a minor radioactive reading of 130 CPM.

After a trial application of FQE Barium-Clear, the scale was dissolved from all sides into liquid phase, which could then be flushed from the system. The flow rate through the pipe returned to full capacity, and the radioactivity was successfully measured at background levels.

Where can FQE Barium-Clear can be applied?

Producing Wells

Batch treatments to clear tubing, casing and perforations

Injection Wells

Batch treatments to clear tubing and perforations effectively lowering injection pressures with minimal downtime

Surface Equipment and Pipeline

Batch treatment of flowlines, pipelines and surface equipment to clear scale

Preventative Maintenance Treatment

Continuous treatment of FQE Barium-Clear to the problem area to prevent the reforming of scale

Current industry practices

Costly, slow and ineffective solutions.

Chelants

Chemical scale removal is often the first, and lowest cost approach, especially when the scale is not easily accessible. With chemically reactive scales such as calcium carbonate, acid treatment to cut through the scale blockage is a traditional practice. Strong chelating agents break-up acid-resistant scale by isolating the scale metallic ions.

However, chelants are slow to react and often offer minimal liquid saturation points. Consequently, the surface area to volume ratio is low and the speed and efficiency of the removal process is too slow to make this chemical treatment a practical removal method.

Mechanical Cleaning

For hard scales, such as barium sulfate, mechanical removal is the technique most often employed. Because scale is rarely deposited evenly on tubular goods, milling technology power requirements vary greatly. When motors cannot supply the power needed for the bit to cut the scale, the motor stalls and the milling process stops.

Even with effective milling practices, residual scale surface in the tubing or other equipment encourages new scale growth and makes inhibition treatments to block nucleation much more difficult. A clean, bare steel surface is more effective in preventing new scale growth.