Chemical Tank Cleaning

Discover our chemical tank cleaning methodology that’s changed the industry standard for cost, time savings, and safety enhancement.

Why choose FQE Chemicals?

-

Improve safety performance: Work is performed in a closed loop system, and no personnel are required to enter the tank.

-

Improve financial performance: Slashes disposal costs, expedites execution, recovers valuable hydrocarbons

-

Improve environmental performance: Minimizes waste, leaving only insoluble, non-hazardous materials for disposal

Contact us today to learn more

50 – 75%

cost savings

By eliminating hazardous disposal

24 hours

vs. 24 days

Chemicals work unlike conventional people-intensive processes

98%

recovery

Of the material that is present in your tank

Improve safety performance

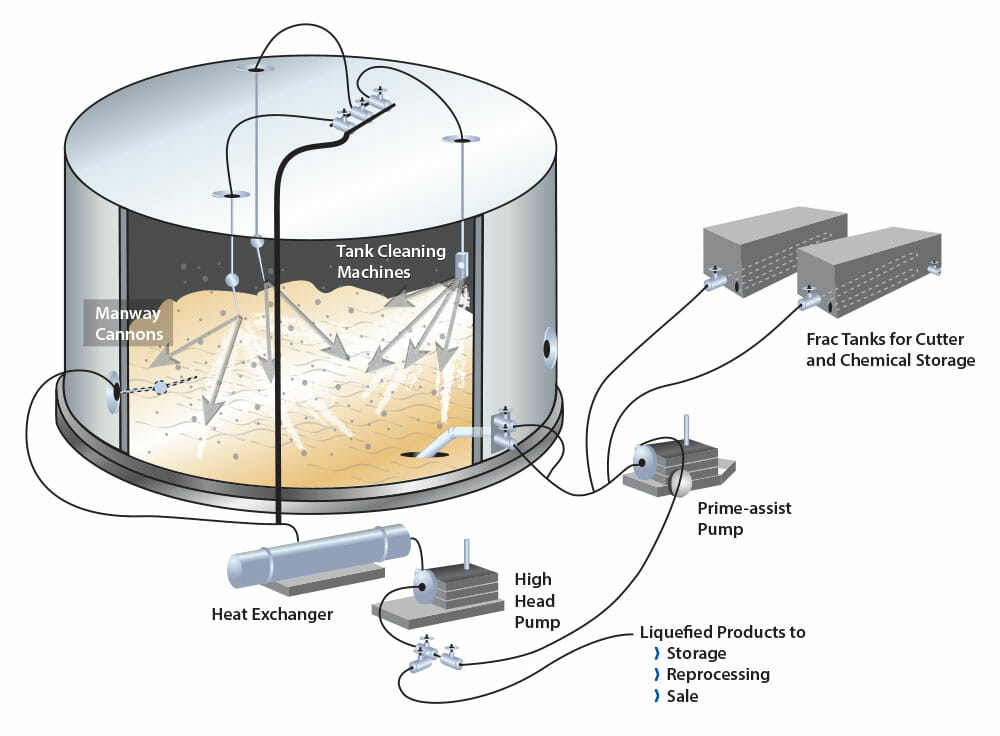

Our chemical cleaning methodology doesn’t require personnel to enter the tank; all work is performed in a closed loop system from outside the tank. Our chemicals are the only thing that works inside. Plus, any hazardous materials are flushed out of the tank without people being exposed to them.

Tanks we clean:

BTEX

Water

Crude oil

Slop

Video Description

This videos shows a crystalline asphalt sample being dissolved with FQE Solvent-H.

Filmed in the FQE Chemicals lab in Deer Park, Texas.

Improve financial performance

FQE Chemicals vs. Mechanical cleaning

Our methodology can create millions of dollars’ worth of financial value plant wide. It’s a significant change in the way the world’s most efficient facilities will deal with tank management.

This financial value from tank cleaning is created in three ways:

Slashing Disposal Costs

The disposal of hazardous waste from your tank can cost between two and four times as much as the actual cleaning of it! Hazardous waste disposal is one of the industry’s most costly burdens, and the fees and potential fines grow increasingly more expensive. Packaging. Transportation. Storage. Then the disposal itself. It really adds up.

With our chemical tank cleaning process, organic solids are dissolved inside the tank, letting you avoid expensive hazardous waste disposal expenses. Only non-hazardous materials are left. And with those costs relatively attractive, you’ve just eliminated one of the largest financial tank cleaning burdens.

Expediting Execution

When you’re facing a narrow turnaround window, our tank cleaning process can be faster than other conventional methodologies, and unlike conventional people-intensive processes, our chemicals and equipment can work 24 hours a day, nonstop. It’s a process that conforms comfortably to even the most heated emergency outage deadline and can be executed with relatively little notice.

Recovering Hydrocarbons

With conventional methodologies, solid organic waste inside the tank is disposed of with great effort and financial loss. Our tank cleaning process actually lets you recover over 98% of the oil that is present in your tank when it’s cleaned! Whether you re-run the recovered hydrocarbon or sell it to other markets, our methodology lets you recover this overlooked resource and tremendous value opportunity.

Improve environmental performance

Our chemical cleaning process for tanks also minimizes waste, leaving only insoluble, non-hazardous materials for disposal. No more reporting tank hazardous waste disposal to your environmental regulatory agency. No more digging up contaminated soil around the tank. Reduce your hazardous volume on a massive scale.