Case History

Online heat exchangers gain improved performance and recover $60,000 in lost production per day for a US refinery through utilizing FQE® Solvent-H+

Results Achieved

Increased crude input by

15,000 bbls/day

Recover $60,000 in lost production per day

Zero downtime in application

Chemicals Utilized

Award-winning asphaltene dispersant and anti-foulant

During a fall outage, a large refinery in the western United States sought out a solution to remove asphaltene fouling and improve the performance of eight online heat exchangers in their crude unit pre-heat train.

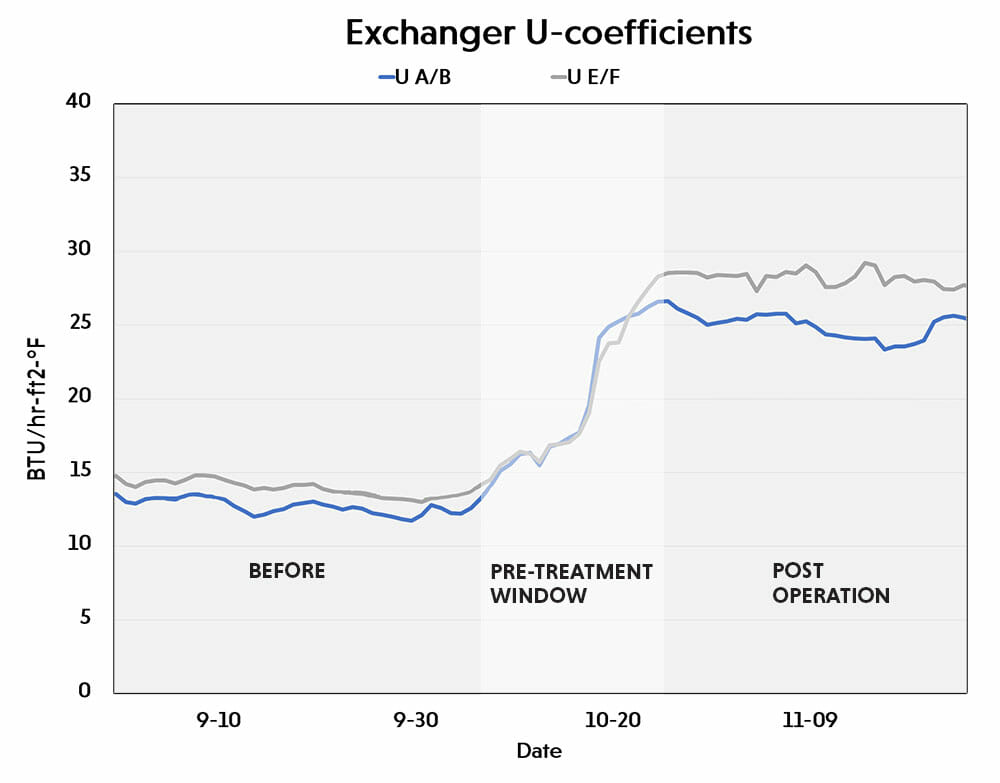

The graph (provided by the client) shows the effectiveness of FQE® Solvent-H+ at increasing the efficiency of the online crude unit heat exchangers.

To dissolve and disperse the heavy hydrocarbons and asphaltenes responsible for efficiency reductions, an online treatment program utilizing FQE Solvent-H+ was applied.

Optimizing the surface interactions of the chemical required adequate surface contact time to ensure an effective treatment. The online high-intensity chemical injection program was completed over 48 hours, with operating temperatures ranging from 400ºF (204ºC) to a maximum of 700ºF (371ºC).

Following the online high-intensity treatment injection in late September, the u-coefficients of each exchanger witnessed increases of up to 120% over the following 30 days. These values leveled off over the next 30 days. Though, post-injection u-coefficients typically remained at least 50% higher than the pre-injection values.

Following the online high-intensity application process, the client was able to confirm several key benefits:

1

Increased System Flow

The client was able to increase crude input by 15,000 bbls/day

2

Millions of Dollars in Recovered Revenue

Due to the increased efficiency and flow and conservatively estimating a $40/bbl market price, the client was able to recover $60,000 in lost production per day. Which equates to over $1.8 million in an average month.

3

Ease of Application and Reliability

FQE Solvent-H+ created no solid by-products as the organic solids remain liquefied, unable to precipitate from the mixture as latent solids. Any potential scaling or blockage issues tied to solids were avoided. As a result, the client was able to improve the reliable operation of the refinery, without shutting down, while effectively addressing their fouling concerns.

As a result of the successful online high-intensity treatment to remove the built-up asphaltene deposits in our client’s facility, we have increased equipment efficiency and production volumes, lowered operating costs and increased reliability through the ease of application.