Applications

Tank Cleaning

Discover our chemical tank cleaning methodology that’s changing the industry standard for both cost and time savings as well as safety enhancement.

Cubic feet of asphaltenes prevented in landfills

Tanks Cleaned

Years of product application

Improve your plant’s safety, financial, and environmental performance with tank cleaning

Over time, hydrocarbon storage tanks containing products ranging from crude oil to asphalt will build a layer of non-flowable material such as asphalt and paraffins. These solids can eventually form a bottom layer many feet deep which rob the tank of storage capacity and can even affect the performance of the pumps feeding the process units. Refiners have even resorted to solutions like adding connections above the solids layer but eventually the tank will need to be cleaned.

Bobcatting the tank clean. Utilizing manpower inside the tank manually utilizing hoses to direct hot cutter stock against the solids. Cutting door sheets into the tank walls. Loading and transporting waste materials. These conventional tank cleaning practices are expensive and risky. But FQE Chemicals offers a chemical tank cleaning methodology that’s changing the industry standard.

No crew member enters the tank, no hazardous waste is generated, and up to 98% of your oil is recovered!

Video Description

This videos shows a crystalline asphalt sample being dissolved with FQE Solvent-H.

Filmed in the FQE Chemicals lab in Deer Park, Texas.

Video Description

Samples Provided by a Port Arthur, TX Refinery. Tested in 5% FQE Solvent-H in Diesel.

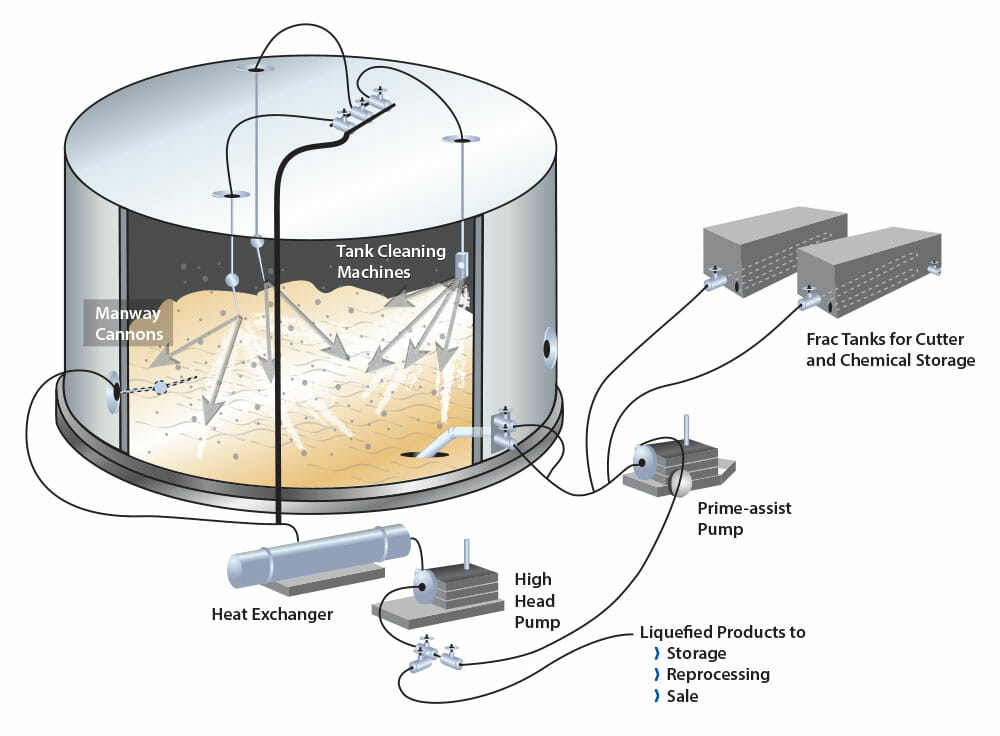

FQE Chemicals’ proprietary tank cleaning process enables you to clean your tanks chemically in a closed loop environment.

First, our chemists custom engineer a solution that liquefies the sludge deposits in your tank that would typically be removed mechanically. Then we blend the solution with a cutter stock and extract the content using standard circulation processes. Lastly, the tank is degassed and polished chemically, achieving a superior level of surface and air cleanliness. And it’s all done without the entry of people or the exit generation of contaminated waste.

Step 1

Recoverable hydrocarbon extraction

A hydrocarbon diluent (cutter stock) is blended with the selected chemical additives (one of FQE® Solvent) and liquid circulation loops are established. Sludge deposits, which would otherwise remain as solids for disposal, are liquefied and can be pumped from the tank more efficiently for further processing.

The liquid circulation loops are established using standard pumping equipment and through manway and roof-mounted cleaning nozzles that can be directed to any location within the tank. Any solids removed by the solvents remain in solution even when pumped to another tank and allowed to sit.

Step 2

Tank cleaning – degassing and polishing

After the hydrocarbon extraction phase is complete, the tank is degassed and cleaned of any nominal hydrocarbons by use of state-of-the-art degassing / decontamination chemistry. These products are non-hazardous water encapsulants which scrub the tank void space of all hydrocarbon and hazardous vapors and clean the tank interior surfaces of residual oil films.

Minimal wastewater is pumped from the tank and processed to separate the residual oils, solutions are non-emulsion forming

Minimal wastewater is pumped from the tank and processed to separate the residual oils, solutions are non-emulsion forming

Oils are recovered and wastewater has low chemical oxygen demand (COD) and biological oxygen demand (BOD) numbers

Oils are recovered and wastewater has low chemical oxygen demand (COD) and biological oxygen demand (BOD) numbers

Tank is now completely gas and hydrocarbon free: any solids that remain can be removed by using vacuum methods, minimizing labor involvement

Tank is now completely gas and hydrocarbon free: any solids that remain can be removed by using vacuum methods, minimizing labor involvement

The Results

1

Less exposure to safety risk

2

Lower project costs

3

Recovered hydrocarbons

4

Less environmental harm

Improve safety performance

Our chemical cleaning methodology doesn’t require personnel to enter the tank; all work is performed in a closed loop system from outside the tank. Our chemicals are the only thing that works inside. Plus, any hazardous materials are flushed out of the tank without people being exposed to them.

Improve financial performance

This methodology can create millions of dollars’ worth of financial value plant wide. It’s a significant change in the way the world’s most efficient facilities will deal with tank management.

This financial value from tank cleaning is created in three ways:

The disposal of hazardous waste from your tank can cost between two and four times as much as the actual cleaning of it! Hazardous waste disposal is one of the industry’s most costly burdens, and the fees and potential fines grow increasingly more expensive. Packaging. Transportation. Storage. Then the disposal itself. It really adds up.

With our chemical tank cleaning process, organic solids are dissolved inside the tank, letting you avoid expensive hazardous waste disposal expenses. Only non-hazardous materials are left. And with those costs relatively attractive, you’ve just eliminated one of the largest financial tank cleaning burdens.

When you’re facing a narrow turnaround window, our tank cleaning process can be faster than other conventional methodologies, and unlike conventional people-intensive processes, our chemicals and equipment can work 24 hours a day, nonstop. It’s a process that conforms comfortably to even the most heated emergency outage deadline and can be executed with relatively little notice.

With conventional methodologies, solid organic waste inside the tank is disposed of with great effort and financial loss. Our tank cleaning process actually lets you recover over 98% of the oil that is present in your tank when it’s cleaned! Whether you re-run the recovered hydrocarbon or sell it to other markets, our methodology lets you recover this overlooked resource and tremendous value opportunity.

Improve environmental performance

Want to protect your crew, save money, and improve your unit’s environmental performance? Contact us today to learn more about our chemical tank cleaning process.